REPAIR OF DIRECT CURRENT GENERATORS

Direct current generators are widely used in the metallurgical industry, transport, mining industries in installations, where a wide and smooth adjustment of the rotation speed is required.

The scope of repair of a direct current generator may include the following technological operations:

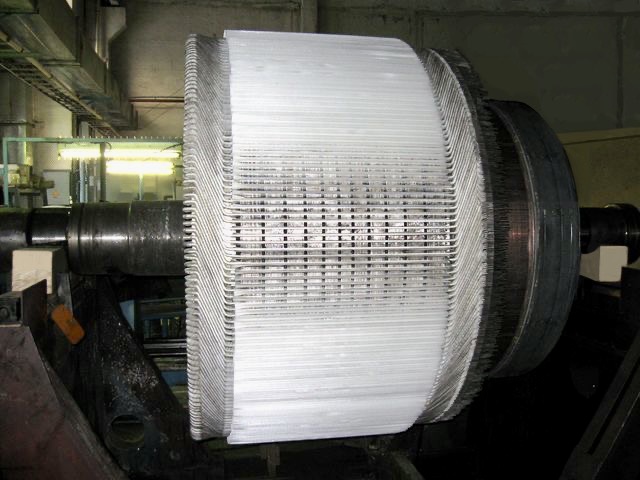

- Overhaul with production of new armature windings and magnetic system;

- Repair of the anchor with the manufacture of windings from new wire;

- Repair of the magnetic system with the manufacture of windings from new wire;

- Repair or manufacture of pole cores;

- Complete repair of the collector with the possibility of pouring or manufacturing and replacing it with a new one;

- Repair of the collector-brush unit;

- Repair of bearing units, shields and restoration of seats;

- Incoming quality control of bearings on the SVK-A machine;

- Repair and manufacture of shafts;

- Color defectoscopy of the shaft to detect signs of fatigue failure;

- Anchor balancing, including in its own bearings as part of the assembled machine;

- Vibrodiagnosis of an electric machine with frequency analysis of the vibration spectrum;

- Diagnostics and testing of electric machines;

- Thermal imaging control of windings and bearing units of an electric machine during acceptance tests.