PRODUCTION OF COMPONENTS FOR ELECTRIC MOTORS

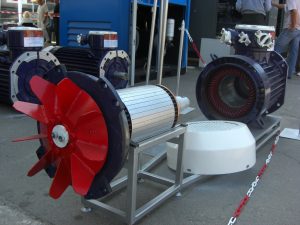

We manufacture rotors of electric motors of the EKV type, EDKOF with copper-brass and aluminum winding rods.

In the construction of the rotors of explosion-proof electric motors of the EKV type, rods are used in the rotor winding, made of copper and soldered with copper shorting rings.

Electric motors with such rotors have a higher overload capacity, increased efficiency due to reduced losses in the copper rotor, economic energy consumption.

A feature of the rotor design

EDKOF electric motor has a cellular rotor winding, made of brass (top cell) and copper (bottom cell) rods, soldered with copper short-circuit rings. In such a design of the rotor winding, melting of the rods is excluded during non-staff modes of operation of the electric motor (frequent starts, overload, load sketches).

Read more

Rotors of electric motors of the EKV type, EDKOF with copper-brass and aluminum winding rods

In the construction of the rotors of explosion-proof electric motors of the EKV type, rods are used in the rotor winding, made of copper and soldered with copper shorting rings.

Electric motors with such rotors have a higher overload capacity, increased efficiency due to reduced losses in the copper rotor, economic energy consumption.

A feature of the design of the rotor of the EDKOF electric motor is the cellular winding of the rotor, made of brass (top cell) and copper (bottom cell) rods, soldered with copper short-circuit rings. In such a design of the rotor winding, melting of the rods is excluded during non-staff modes of operation of the electric motor (frequent starts, overload, load sketches).

Sections of stator windings of electric motors

The equipment of the technological line for the production of sections of high-voltage and low-voltage motors contains in its composition the classic elements of the production of sections (coil, stretching, formation of frontal parts, isolation of groove parts of sections), as well as modern technological solutions (vacuum infiltration, baking sections) which allows you to obtain an insulation system of classes "F" and "H". is

Modern technology of baking and pressing the groove part of the sections using thermo-reactive insulation ("MONOLIT-2M")

- Provides high electrical and physical-mechanical strength, monolithicity of the insulating material;

- EXCLUDES the occurrence of folds in it, air inclusions;

- Improves heat transfer from the section;

- Significantly reduces the possibility of corona discharges between insulation layers;

- Allows forming the dimensions of the groove part with an accuracy of 0,1 mm to ensure minimum clearances between the section and the stator slot.

PSDKTL wire is used in the manufacture of sections of stator windings (the tire is insulated with impregnation with KO-916 varnish). All sections are checked for geometric dimensions and insulation strength tests after manufacturing and during installation.

The plant's equipment allows the manufacture of sections of stator windings for any type of electric motors with an operating voltage of up to 10,000V and a coil length from 0,7 m to 4,5 m of the specified class of heat resistance