ASYNCHRONOUS EXPLOSION-PROOF ELECTRIC MOTORS DAOV SERIES

Three-phase asynchronous explosion-proof high-voltage electric motors with a short-circuited rotor of the DAOV type are intended for the equipment of various pumps, fans, stirrer, lifting mechanisms, etc, working in explosive areas, underground workings of mines, mines and their ground buildings, dangerous due to mine gas or dust (explosion protection marking – RV 4B (RVExdl)).

SPECIFICATIONS

Engines must meet the requirements of the Technical Regulations of Equipment and Protective Systems, intended for use in a potentially explosive atmosphere, DSTU EN(Jesus) 60034-1, DSTU EN(Jesus) 60079-11, DSTU 2331, DSTU 7113, DSTU 7114, GUEST 24719, current technical conditions and a set of design documentation according to the specification EDKR.526826.000.

The DAOV series of electric motors is manufactured with the height of the axis of rotation - 450, 560 and 630 mm.

Motors are designed to operate from an alternating current network with a frequency of 50 Hz, voltage 6000 AT.

Type of climatic execution of engines – AT 2, 5 for GOST 15150.

Nominal mode of operation – long S1 DSTU IES 60034-1.

Construction of engines – IM1001, IM3001 DSTU EN(Jesus) 60034-7.

The degree of protection is IR54, external fan - IR20 according to DSTU EN(IEC) 60034-5.

The method of engine cooling is IC141 and IC151 according to DSTU EN(Jesus) 60034-6.

Depending on the requirements for vibration, motors belong to category N according to GOST 20815.

Maximum permissible sound power levels, adjusted according to characteristic A, in engine idling mode should not exceed the values, established DSTU EN(Jesus) 60034-9 for class products 1 according to GOST 16372.

Direct starting of the engine is ensured as with nominal voltage, as well as when the network voltage drops during the start-up time 0,8 Unom. Engines must be designed for 2400 inclusions per year, allow three starts in a row from a cold state, two hot starts, with an interval between starts from 3 to 5 min and the permissible number of starts from 6 to 8 on age.

Engines have rolling bearings. Bearing grease is consistent, Lubrication can be replenished without stopping the electric motor. Bearing temperature control is carried out by resistance thermoconverters.

Motors are connected to the drive mechanism using toothed or elastic sleeve-finger couplings. Insulating materials of the stator winding of the heat resistance class – “F”. Insulation of the stator winding is of the thermoreactive type “Monolith-2”.

The input box has three power terminals and an earth terminal (internal and external), allows insertion of armored cable with copper or aluminum cores, providing dry processing or filling with cable mass. The temperature of the winding and the stator core is controlled by six thermal transducers, embedded in the stator groove.

Motors are manufactured in several variants of heat control of the stator winding, bearings, housing and vibration control. For such versions, additional terminal boxes on the stator housing are provided.

Motors allow right and left direction of rotation. The direction of rotation is changed only from a state of rest. Optimal design, high quality materials and components, advanced manufacturing technology ensures a high technical level, guarantee safety, reliability and ease of use.

Requirements for paint coatings in accordance with DSTU ISO 12944-1 and design documentation. The painting system is not lower than S5.03 for corrosion category C5-M, respectively

DSTU ISO 12944-5.

In the process of manufacturing parts and assembly units, continuous control of explosion protection parameters and hydraulic testing of pressure shells is carried out in accordance with the requirements of the design documentation, DSTU EN 60079-1, DSTU 7113.

The structure of the conventional designation of electric motors of the DAVO series:

| 1 | 2 | 3 | 4 | 5 | |||

| DAOV | – | XXX | – | XXX | – | H | U2.5 |

| field no | Designation code | Decoding the designation code |

|

1 |

Designation of the series |

DAOV – asynchronous blower motor

explosion-proof |

| 2 | Gauge | height of the axis of rotation, -450, -560,-630 mm |

| 3 | Power | kW |

| 4 | Number of poles | 2p=4,6,8 |

| 5 | Climatic performance | according to GOST 15150 |

According to the installation and connection size, the electric motors of the series, that are produced.

interchangeable with electric motors similar electric motors of other manufacturers.

The technical characteristics of the engines are given in the table 1

Table 1

|

Type engine |

Power, kW |

Slip, % |

Stator current, A |

efficiency, % |

cosϕ |

Mpusk/Mnom |

Istart/Inom |

Mmax/Mnom |

Moment of inertia of the rotor, kg*m2 |

The maximum permissible level of sound power, Lw, Db(A) |

Type and level of explosion protection |

|

| Synchronous rotation frequency n=1500 rpm | ||||||||||||

| DAOV-450-200-4 | 200 | 1,5 | 23,4 | 94,0 | 0,89 | 1,0 | 6,0 | 2,5 | 8 | 106 |

PBExdI PB-4B |

|

| DAOV -450-250-4 | 250 | 1,5 | 28,6 | 94,5 | 0,89 | 1,1 | 6,0 | 2,5 | 9 | 108 | ||

| DAOV -450-315-4 | 315 | 1,5 | 35,5 | 95,0 | 0,9 | 1,1 | 6,0 | 2,5 | 11 | 108 | ||

| DAOV -450-400-4 | 400 | 1,5 | 44,4 | 95,0 | 0,91 | 1,1 | 6,0 | 2,5 | 13 | 108 | ||

| DAOV -560-500-4 | 500 | 1,0 | 56,3 | 95,3 | 0,9 | 1,3 | 6,5 | 2,5 | 15 | 108 | ||

| DAOV -560-630-4 | 630 | 1,0 | 70,9 | 95,0 | 0,9 | 1,3 | 6,0 | 2,5 | 22 | 111 | ||

| DAOV -560-800-4 | 800 | 0,9 | 89,6 | 95,3 | 0,9 | 1,3 | 6,5 | 2,5 | 26 | 111 | ||

| DAOV -560-1000-4 | 1000 | 1,0 | 112,0 | 95,5 | 0,9 | 1,3 | 6,0 | 2,5 | 50 | 111 | ||

| DAOV -630-1250-4 | 1250 | 1,0 | 139,8 | 95,6 | 0,9 | 1,1 | 6,5 | 2,3 | 55 | 113 | ||

| DAOV -630-1600-4 | 1600 | 1,0 | 178,2 | 96,0 | 0,9 | 1,1 | 6,5 | 2,3 | 64 | 113 | ||

| DAOV -630-2000-4 | 2000 | 1,0 | 222,3 | 96,2 | 0,9 | 1,1 | 7,0 | 2,3 | 73 | 113 | ||

| Synchronous rotation frequency n=1000 rpm | ||||||||||||

| DAOV -450-200-6 | 200 | 0,8 | 24,6 | 93,7 | 0,84 | 1,0 | 6,5 | 2,1 | 15 | 102 |

PBExdI PB-4B

|

|

| DAOV -450-250-6 | 250 | 0,7 | 32,0 | 94,2 | 0,84 | 1,0 | 6,5 | 2,1 | 17 | 105 | ||

| DAOV -450-315-6 | 315 | 0,7 | 40,0 | 94,7 | 0,84 | 1,0 | 6,5 | 2,1 | 19 | 105 | ||

| DAOV -560-400-6 | 400 | 1,2 | 47,8 | 94,8 | 0,85 | 1,1 | 6,0 | 2,2 | 22 | 105 | ||

| DAOV -560-500-6 | 500 | 1,1 | 59,6 | 94,9 | 0,85 | 1,1 | 6,0 | 2,2 | 34 | 105 | ||

| DAOV -560-630-6 | 630 | 1,0 | 74,8 | 95,3 | 0,85 | 1,1 | 6,0 | 2,2 | 41 | 108 | ||

| DAOV -560-800-6 | 800 | 1,0 | 94,8 | 95,5 | 0,85 | 1,1 | 5,5 | 2,2 | 68 | 108 | ||

| DAOV -630-1000-6 | 1000 | 1,0 | 117,7 | 96,2 | 0,85 | 1,0 | 6,5 | 2,2 | 79 | 110 | ||

| DAOV -630-1250-6 | 1250 | 1,0 | 147,0 | 96,3 | 0,85 | 1,0 | 6,0 | 2,1 | 90 | 110 | ||

| Synchronous rotation frequency n=750 rpm | ||||||||||||

| DAOV -450-200-8 | 200 | 1,1 | 25,9 | 93,0 | 0,8 | 1,0 | 6,0 | 2,2 | 20 | 99 |

PBExdI PB-4B |

|

| DAOV -450-250-8 | 250 | 1,1 | 32,0 | 94,1 | 0,8 | 1,0 | 6,0 | 2,2 | 23 | 102 | ||

| DAOV -560-315-8 | 315 | 1,3 | 40,0 | 94,7 | 0,8 | 1,0 | 6,0 | 2,2 | 37 | 102 | ||

| DAOV -560-400-8 | 400 | 1,3 | 50,6 | 95,0 | 0,8 | 1,0 | 6,0 | 2,2 | 43 | 102 | ||

| DAOV -560-500-8 | 500 | 1,3 | 63,2 | 95,2 | 0,8 | 1,0 | 6,0 | 2,2 | 50 | 102 | ||

| DAOV -560-630-8 | 630 | 1,3 | 79,4 | 95,5 | 0,8 | 1,0 | 6,0 | 2,2 | 99 | 105 | ||

| DAOV -630-800-8 | 800 | 1,3 | 100,3 | 95,9 | 0,8 | 1,0 | 6,0 | 2,0 | 116 | 105 | ||

| DAOV -630-1000-8 | 1000 | 1,3 | 125,3 | 96,0 | 0,8 | 1,0 | 6,0 | 2,1 | 138 | 105 | ||

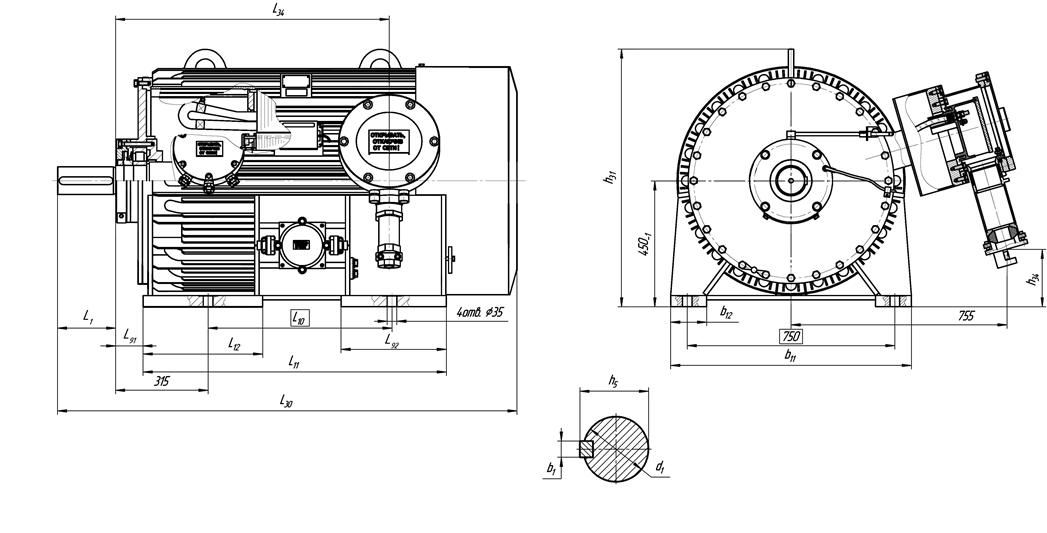

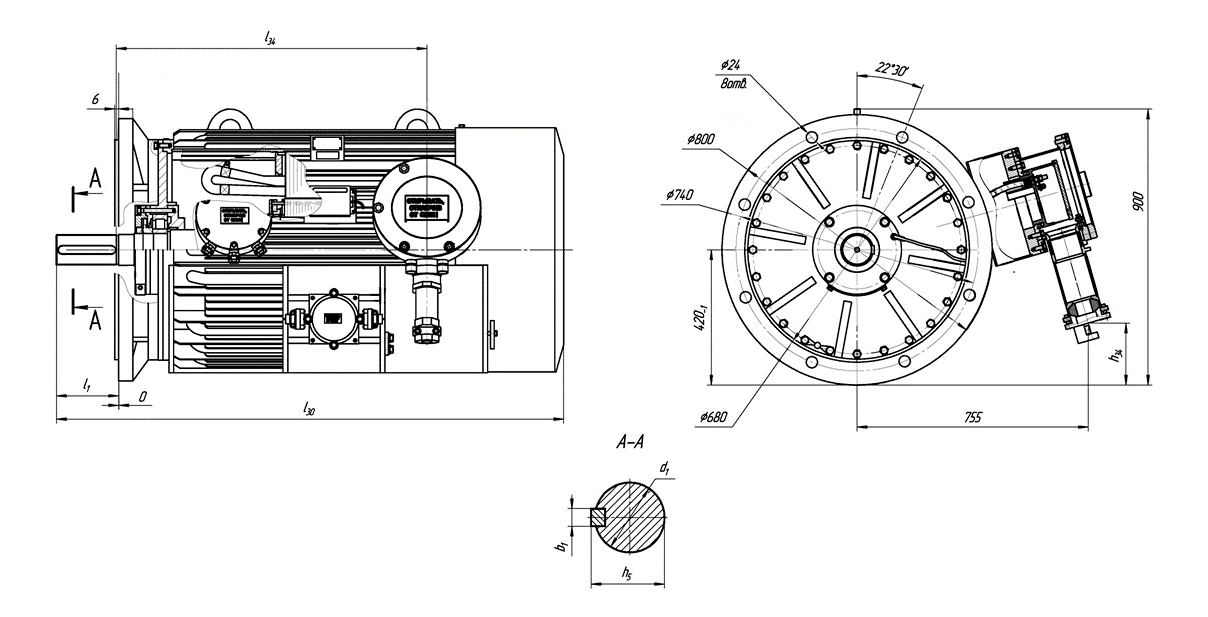

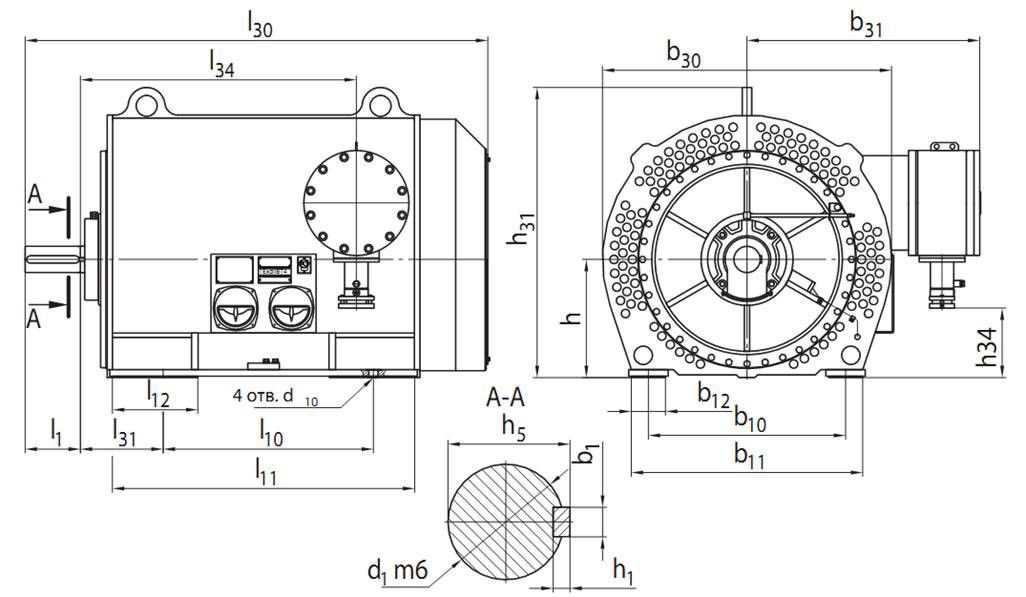

The overall and connecting dimensions of the motors are given in the table 2.

Overall and installation and connecting dimensions of electric motors DAOV-450:

IM1001 (on paws)

IM3001 (flange)

Overall and connecting dimensions of DAOV-560,-630 electric motors:

Table 2.

|

Engine type |

Gaugeand paboutzmandpand, mm | Installation and connection dimensions, mm | Mass | ||||||||||||||||||||||

| l30 | b30 | b31 | h31 | l1 | l10 | l11 | l12 | l31 | l34 | l91 | d1 | d10 | b1 | b10 | b11 | b12 | b33 | h | h1 | h5 | h12 | h34 * | N | kg | |

| DAOV-450-200-4 | 1585

1660 |

1100 |

885 |

1105 |

210 |

630 | 1050

1095 10711700 |

325 |

315 |

790

925 |

99 |

100 |

35 |

28 |

750 |

900 |

130 |

740 |

450 |

16 |

106 |

30 |

145 115 |

1 |

2008/2160 |

| DAOV-450-250-4 | 1635 | 710 | 1095 | 325 | 860 | 2180/2260 | |||||||||||||||||||

| DAOV-450-315-4 | 1725 | 1170 | 950 | 2410/2760 | |||||||||||||||||||||

| DAOV-450-400-4 | 1897 | 800 | 1350 | 400 | 1100 | 2410/2460 | |||||||||||||||||||

| DAOV-450-200-6 | 1717 | 710 | 1170 | 325 | 870 | 2380/2452 | |||||||||||||||||||

| DAOV-450-250-6 | 1857 | 1310 | 990 | 2750/2825 | |||||||||||||||||||||

| DAOV-450-315-6 | 1957 | 800 | 1410

|

400 | 1120 | 3050/3136 | |||||||||||||||||||

| DAOV-450-200-8 | 1800 | 710 | 1250 | 325 | 990 | 2960/3016 | |||||||||||||||||||

| DAOV-450-250-8 | 1900 | 800 | 1350 | 400 | 1100 | 3050/3136 | |||||||||||||||||||

| DAOV-560-500-4 | 1745 | 1210 | 960 | 1270 |

210 |

630 | 1120 |

350 |

355 |

925 |

115 |

110 |

42 |

32 |

950 |

1130 |

165 |

810 |

560 |

18 |

117 |

35 |

445 |

3450 | |

| DAOV-560-630-4 | 710 | 3850 | |||||||||||||||||||||||

| DAOV-560-800-4 | 1980 | 1300 | 950 | 1315 | 800 | 1320 | 1125 | 850 | 4600 | ||||||||||||||||

| DAOV-560-1000-4 | 900 | 5635 | |||||||||||||||||||||||

| DAOV-560-400-6 | 1745 | 1210 | 960 | 1270 | 630 | 1120 | 925 | 810 | 3910 | ||||||||||||||||

| DAOV-560-500-6 | 710 | 4370 | |||||||||||||||||||||||

| DAOV-560-630-6 | 1980 | 1300 |

950 |

1315 | 800 | 1320 | 1125 | 850 | 5175 | ||||||||||||||||

| DAOV-560-800-6 | 900 | 6440 | |||||||||||||||||||||||

| DAOV-560-315-8 | 1745 | 1210 | 960 | 1270 | 630 | 1120 | 925 | 810 | 4025 | ||||||||||||||||

| DAOV-560-400-8 | 710 | 4485 | |||||||||||||||||||||||

| DAOV-560-500-8 | 1980 | 1300 |

950 |

1315 | 800 | 1320 | 1125 | 850 | 5290 | ||||||||||||||||

| DAOV-560-630-8 | 900 | 6555 | |||||||||||||||||||||||

| DAOV-630-1250-4 | 2200 | 1450 | 1000 | 1460 |

250

|

1000 | 1420 |

450 |

375 |

1250 |

108 |

140 |

36 |

1250 |

1440 |

240 |

955 |

630 |

20 |

156 |

620 |

2 |

6600 | ||

| DAOV-630-1600-4 | 2300 | 1120 | 1550 | 1380 | 7210 | ||||||||||||||||||||

| DAOV-630-2000-4 | 2500 | 1530 | 1035 | 1500 | 1250 | 1760 | 1590 | 1000 | 640 | 8370 | |||||||||||||||

| DAOV-630-1000-6 | 2300 | 1450 | 1000 | 1460 | 1120 | 1550 | 1380 | 955 | 620 | 6500 | |||||||||||||||

| DAOV-630-1250-6 | 2500 | 1530 | 1035 | 1500 |

|

1250 | 1760 | 1590 | 1000 | 640 | 7560 | ||||||||||||||

| DAOV-630-800-8 | 2300 | 1450 | 1000 | 1460 | 1120 | 1550 | 1380 | 955 | 620 | 6970 | |||||||||||||||

| DAOV-630-1000-8 | 2500 | 1530 | 1035 | 1500 | 1250 | 1760 | 1590 | 1000 | 640 | 8230 | |||||||||||||||

Note – N is the number of keys at the end of the shaft

* In the numerator, the height to perform IM1001 in the denominator – to perform IM3001